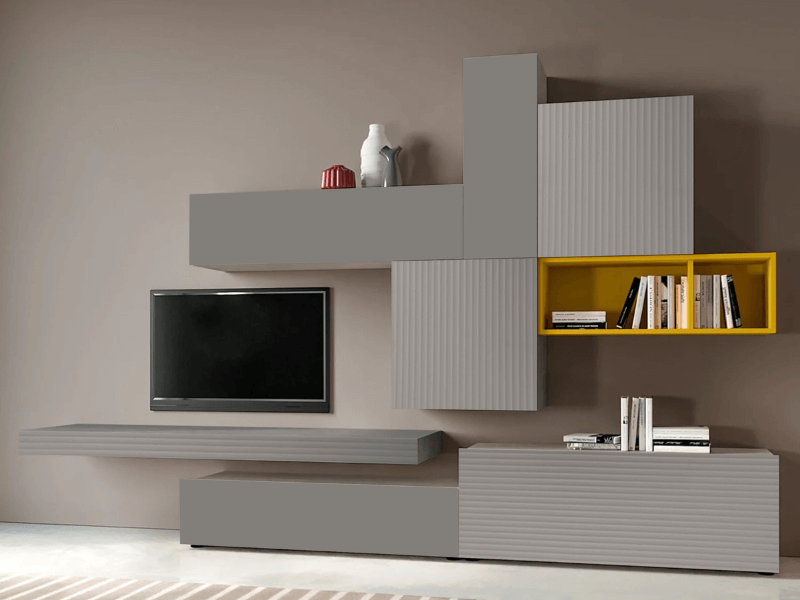

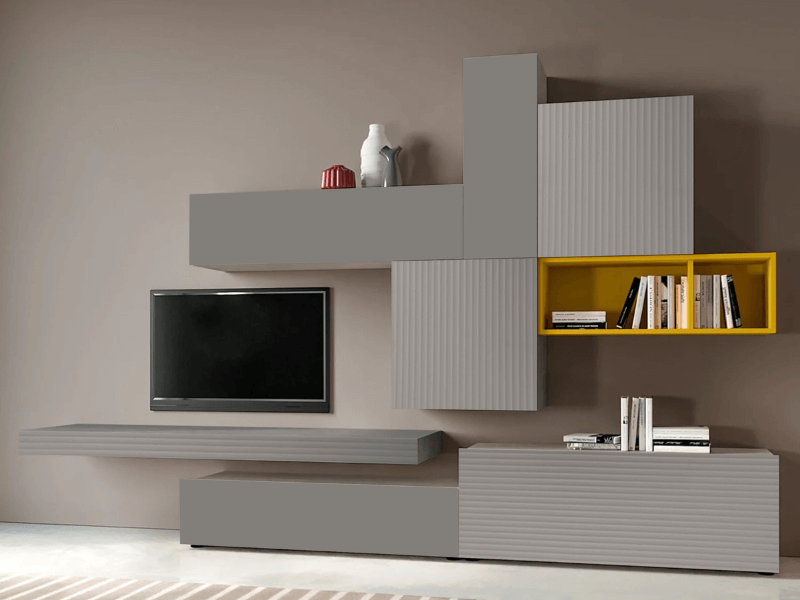

In contemporary interior architecture, surface texture is as critical as color. Fluted panels linear decorative cladding characterized by engineered vertical grooves have emerged as the definitive solution for adding depth to flat surfaces .

Unlike standard wallpaper or paint, fluted wall panels offer architectural rigidity and tangible rhythm. Whether you are designing a high-traffic commercial lobby or a residential accent wall, selecting the correct fluted panel material requires an understanding of composition, acoustics, and installation mechanics.

What Are Fluted Panels?

Technically, flute panels derive their name from “fluting” the shallow, concave grooves found on classical Doric columns. In modern applications, this profile is extruded or carved into sheets to create a continuous linear pattern.

While they add immense visual interest, their primary function in modern civil engineering is twofold:

- Visual Correction: Vertical flutes draw the eye upward, optically increasing the ceiling height.

- Surface Protection: Rigid panels protect drywall from impact damage in high-traffic zones.

Difference Between Fluted Panel and Louvers

A common confusion among homeowners and even junior designers is the difference between fluted panel and louvers.

While Both Fall Under Linear Claddings, Their Geometric Profiles Differ:

- Fluted Panels: Feature concave (inward curving) grooves. They create soft, rolling shadows and are smoother to the touch.

- Louvers (or Slats): Feature convex (outward projecting) rectangular or square fins. They create sharp, high-contrast shadow lines.

Suggested Read : Fluted PVC Panels

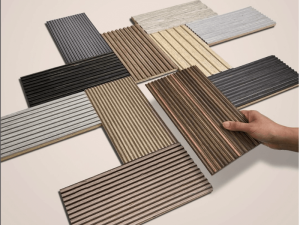

Selecting the Right Fluted Panel Material

The longevity of your wall fluted panel depends entirely on the substrate material.

1. Charcoal & Polystyrene (The Designer’s Choice)

Popularized by brands like Ventura and EuroPratik, these are made from high-density polystyrene (HDPS). This material allows for incredible versatility in finish, seen in ranges like the Ventura Ikon Collezione (for metallic and marble looks), the Ventura Fabrika Collezione (for fabric-inspired textures), or the Ventura Fusion Collection (for mixed-material aesthetics).

- Pros: Extremely sharp definition of flutes, lightweight, and available in metallic/mirror finishes.

- Best For: Highlight walls, TV units, and ceilings.

2. Flute PVC Panel Design (The Waterproof Standard)

Polymer composites have revolutionized cladding. Flute PVC panel design options are market leaders due to durability.

- Pros: 100% Waterproof, Termite-proof, and flexible (can curve around columns).

- Application: Ideal for bathrooms, kitchens, and damp walls where wood would rot.

3. Fiber Cement (The Exterior & Safety Expert)

Competitors like Everest specialize in this. These are cement-bonded cellulose panels.

- Pros: Class-A Fire Rating (Non-combustible), weather-proof.

- Application: Exterior facades, fireplace cladding, and public corridors.

4. Wood & MDF (The Traditional Choice)

Natural wood offers unmatched warmth but is susceptible to humidity.

- Warning: Avoid MDF cores in Indian basements or coastal homes due to swelling risks. For such areas, a wood-look engineered option like the Ventura Legno Collection is often a safer, moisture-resistant alternative that retains the authentic grain appearance.

5. Metal Fluted Panel (The Industrial Edge)

Usually fabricated from aluminum or galvanized steel.

- Pros: Extreme impact resistance and sleek industrial aesthetics.

Related Read : Fluted Wall Panels Design

Master Comparison Table: Which Material is Best?

|

Feature

|

PVC / WPC |

Charcoal (Polystyrene) |

Fiber Cement |

MDF / Wood

|

|

Water Resistance

|

100% Waterproof |

Waterproof |

Weatherproof |

Low (Swells)

|

|

Fire Safety

|

Self-Extinguishing |

Low |

Class A (Best) |

Flammable

|

|

Flexibility

|

High (Curves) |

Medium |

Rigid |

Rigid

|

|

Finish

|

Pre-finished |

Metallic/Matte |

Paintable |

Paintable/Veneer

|

|

Best Use

|

Damp Walls |

TV Units / Decor |

Exteriors / Facades |

Dry Bedrooms

|

Technical Specifications (Standard Indian Market Sizes)

Before planning your layout, note these standard dimensions to minimize wastage:

- Standard Height: 8 ft, 9.5 ft (Floor to Ceiling), and 10 ft.

- Panel Width: Typically 1220mm (4ft sheet) or 150mm – 200mm (Interlocking planks).

- Thickness: 12mm to 28mm depending on the depth of the flute.

Design Applications: Beyond the Accent Wall

- Hidden Doors: Use fluted wall panels to camouflage service doors or powder room entries. The vertical lines hide the door gaps perfectly.

- Curved Surfaces: Use flexible PVC flutes to wrap around circular structural columns.

- Furniture Cladding: Apply micro-fluted panels to drawer fronts or kitchen islands for a texture upgrade.

Acoustic Benefits: Diffusion vs. Absorption

Do fluted wall panels help with sound? Yes, but technically, they act as diffusers.

The semi-circular geometry of the flutes breaks up sound waves, preventing direct echoes (flutter echoes). For true soundproofing, installing these panels over a high-density acoustic foam is recommended.

Installation Guide: How to Fix Fluted Panels

Installing fluted panels is a precision task. Here is the standard procedure for a secure fix:

- Surface Prep: Ensure the base wall is plumb (vertically straight). Use a 6mm plywood grid if the wall is uneven.

- Cutting: Use a circular saw with a fine-tooth blade to cut the panels to height.

- Adhesion: Apply heavy-duty construction adhesive (like Liquid Nails or PU Glue) to the back of the panel in a zig-zag pattern.

- Interlocking: Most flute panels come with a tongue-and-groove system. Slot the panels together to hide the joinery.

- Mechanical Fixing: For heavy panels (MDF/Fiber Cement), shoot headless pins or screws through the groove (the valley) to anchor them to the wall.

Also Read : How to Choose the Right Fluted Panels for Your Home’s Interiors?

Conclusion

Fluted panels are more than just a trend; they are a versatile architectural tool that solves aesthetic and structural challenges simultaneously. Whether you opt for a waterproof flute PVC panel design, a fire-safe fiber cement cladding, or a luxurious charcoal finish, ensure your choice aligns with the environmental conditions of the room.

Explore the complete range of engineered fluted panels at Ventura’s Experience Centre.

Frequently Asked Questions (FAQs)

1. Can fluted panels be installed on damp walls?

If you are using a flute PVC panel design or Charcoal panel, yes. These are waterproof. However, for MDF or wood panels, you must treat the dampness first and install a waterproof ply backing.

2. Can I paint over fluted panels?

Yes, if they are made of MDF, Wood, or Fiber Cement. You can spray paint them to match your decor. PVC and Charcoal panels usually come pre-finished and are difficult to paint without a specialized plastic primer.

3. How do I clean the grooves in fluted panels?

Dust tends to settle in the grooves. Use a vacuum cleaner with a brush attachment or a microfiber duster. For stains on metal fluted panels or PVC, wipe with a damp cloth and mild detergent.

4. Are fluted panels expensive?

Cost varies by material. PVC panels are generally the most budget-friendly. Charcoal panels are mid-range, while Solid Wood and Metal are premium options.

5. Do fluted panels reduce noise?

They help improve sound quality by reducing echo (diffusion), but they do not block sound transmission (insulation) on their own.

Manish Maheshwari

Position: Founder – Ventura International Pvt Ltd.

Education: IIT Roorkee (B.E. – Mechanical Engineering) and IIM Lucknow (Marketing & Finance)

Manish Maheshwari, the visionary Co-founder of Ventura International. With a background in Engineering from IIT Roorkee and an MBA from IIM Lucknow, his expertise spans across Finance, Economics, and Strategy. At the helm of Ventura’s vision, Manish leads the charge in planning and executing strategies for growth and innovation. His unwavering passion ensures that Ventura sets the bar high, always striving for unparalleled excellence.