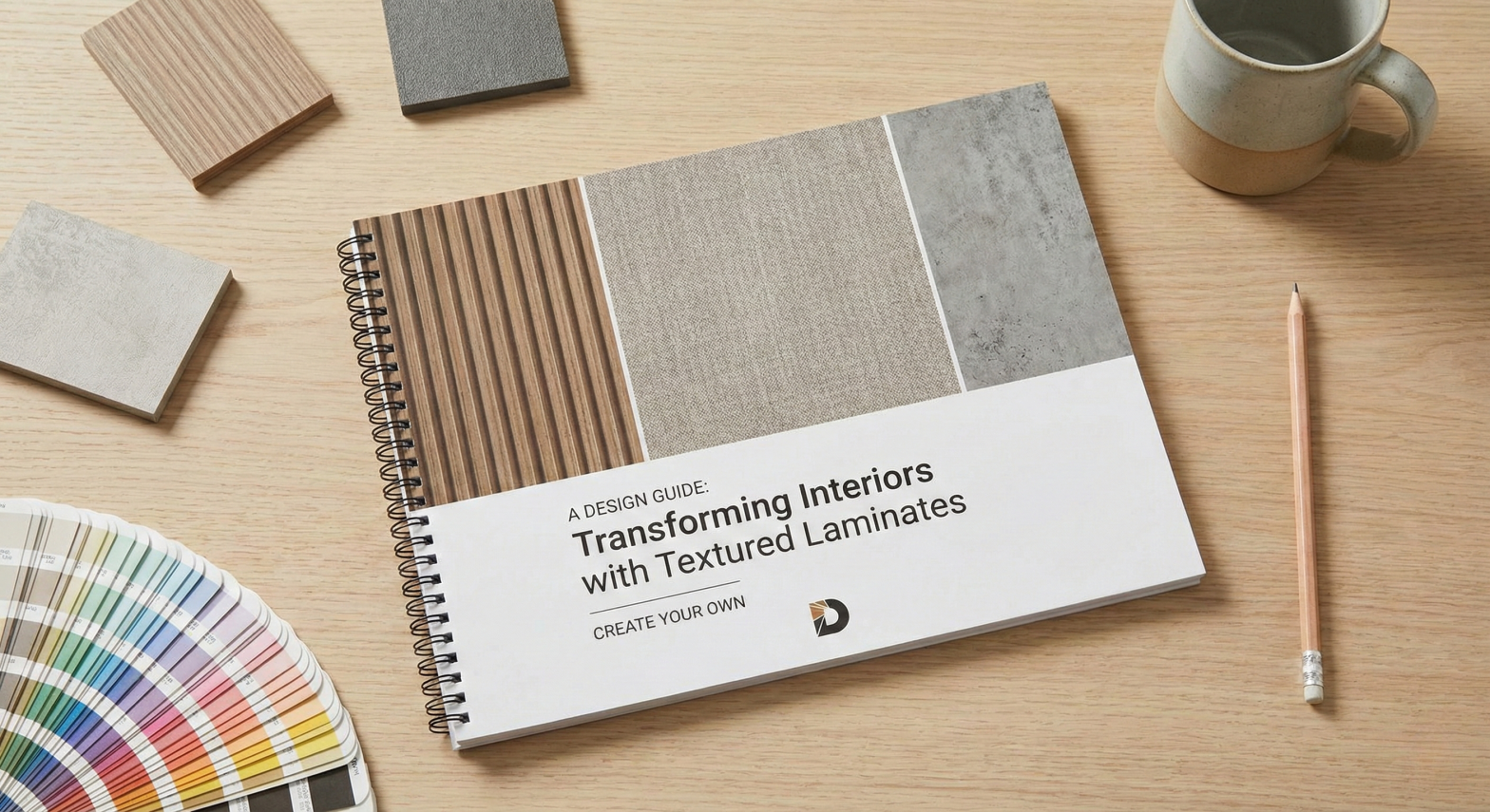

The architectural narrative in India is evolving. Design preferences in modern Indian residences and commercial spaces are shifting away from purely visual, high-gloss designs toward spaces that prioritize tactile engagement. While flat finishes once dominated the market, the modern specification focus is moving decisively towards high-quality textured laminates, such as the versatile Ventura Vivid Collezione laminate series. These surfaces introduce depth, warmth, and an authentic character that flat finishes often lack.

Advancements in high-pressure manufacturing now enable a premium textured laminate to offer a sensory experience that closely emulates natural materials. This shift aligns with the principles of Bibliophile Design, which suggests that tactile connections to natural textures such as wood grain or stone can support psychological well-being in indoor environments by reducing perceived stress.

This guide provides a technical and aesthetic breakdown of these surfaces from Embossed-in-Register (EIR) technology to a comparative performance analysis—assisting you in making an informed specification using trusted lines like the Unicorn MCS Laminate.

What is a Textured Laminate?

A textured laminate is a high-performance surfacing material engineered to replicate both the visual appearance and the physical touch of substrates like wood, stone, or fabric. Technically, it is a High-Pressure Laminate (HPL) composed of multiple layers of kraft paper impregnated with phenolic resin, a decorative paper layer, and a clear melamine overlay that protects the surface texture.

According to the NEMA LD 3 standard for High-Pressure Decorative Laminates, these layers are fused under high hydraulic pressure (exceeding 1,000 psi) and specific thermosetting temperatures (approx. 275°F / 135°C) to create a unified, non-porous sheet that resists delamination. Unlike standard flat laminates, a textured laminate features a mechanically embossed surface layer that enhances light diffusion and adds architectural realism to interiors.

Textured Laminate vs. High Gloss: A Comparative Analysis

One of the most common specification dilemmas is choosing between a matte/textured laminate and a high-gloss look. While glossy finishes offer a contemporary sheen, they are prone to “telegraphing” a phenomenon where substrate imperfections (such as uneven plywood calibration) become visible on the surface.

Related Read : Glossy Laminates: Complete Guide to Benefits, Uses & Designs

Material Performance Comparison

| Feature |

Textured Laminate |

High Gloss Laminate |

| Scratch Visibility |

Low (Texture profile visually disrupts light, masking micro-abrasions) |

High (Scratches interrupt light reflection and are easily visible) |

| Maintenance |

Moderate (Deep textures require specific agitation techniques for cleaning) |

High (Requires frequent micro-fiber polishing) |

| Visual Depth |

High (Simulates organic material depth and tactile realism) |

Flat (High reflectivity, often looks artificial) |

| Telegraphing |

Low (Matte/embossed surface helps conceal substrate undulations) |

High (Amplifies substrate unevenness) |

| Best For |

High-traffic horizontal surfaces (kitchens, desks) and vertical cabinetry |

Statement walls, low-contact vertical areas |

Trending Textures for 2026: Technology & Aesthetics

The market for textured laminates is currently driven by “Haptic Appeal” , an emphasis on how a material feels, not just how it looks.

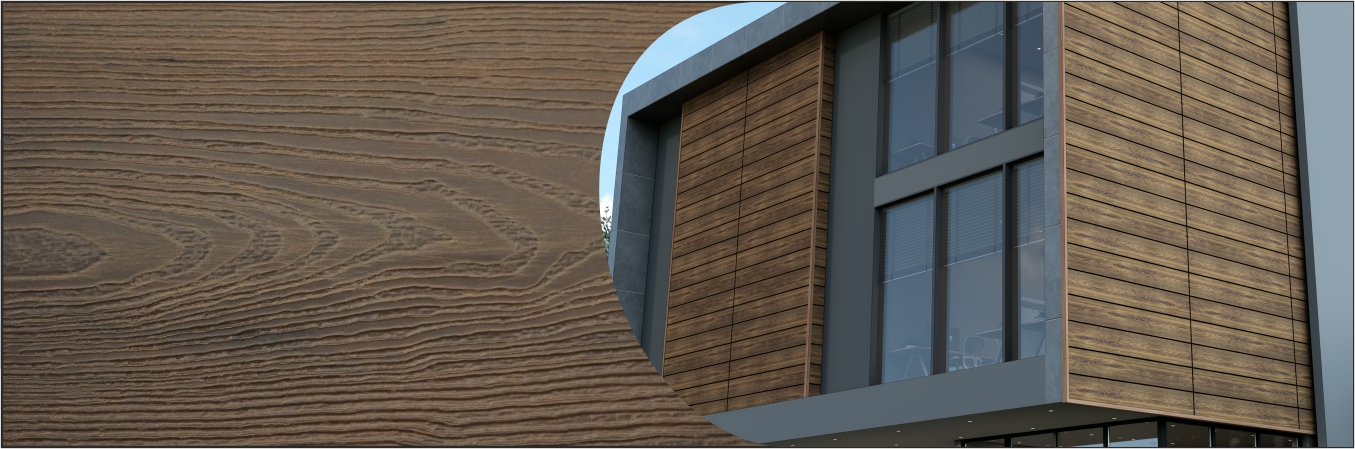

1. Synchronized Woodgrain (Embossed-in-Register)

Technically known as Embossed-in-Register (EIR), this is the benchmark for premium textured laminates. In standard woodgrain laminates, the printed pattern and the surface texture may not align. However, with EIR technology, the steel press plate is synchronized precisely with the decorative paper’s grain pattern during the pressing cycle.

- Recommendation: The Ventura Amber Wood Laminate utilizes this technology to ensure that if you see a knot in the wood design, you feel the knot texture. This creates a veneer-grade aesthetic with the superior surface wear resistance of HPL.

2. Anti-Fingerprint & Soft-Touch Finishes

Combining utility with aesthetics, these surfaces address a major drawback of dark matte laminates: oil visibility. New Electron Beam Curing (EBC) processes have allowed for the creation of super-matte surfaces that are highly resistant to thermal healing and fingerprints.

- Recommendation: The Ventura Skin collection is engineered specifically for this purpose. It is ideal for handle-less kitchen cabinets where tactile interaction is frequent, offering a soft, velvet-like touch while remaining highly resistant to scuffs.

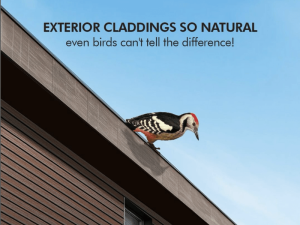

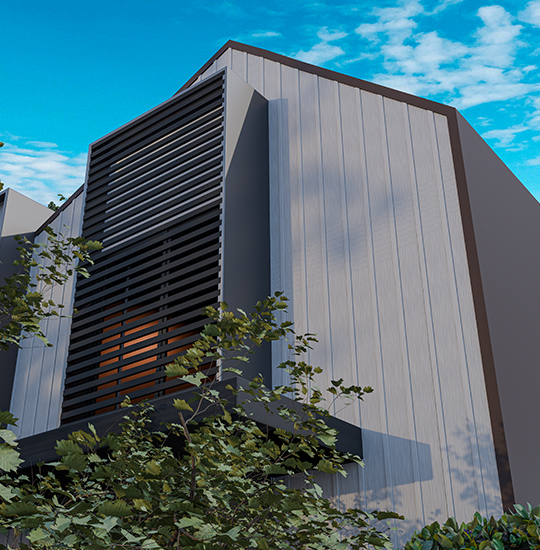

3. Stone & Concrete Textures

Industrial aesthetics remain prevalent. Stone-finish textured laminates offer the visual weight of concrete or marble without the structural load or porosity issues associated with natural stone. Unlike highly porous natural stone, which requires regular sealing to prevent staining, High-Pressure Laminates (HPL) are non-porous surfaces that inherently resist moisture absorption.

- Recommendation: The Marble & Stone laminate series captures this raw elegance perfectly. Unlike highly porous natural stone, which requires regular sealing to prevent staining, these HPL surfaces inherently resist moisture absorption.

4. Woven & Organic Textures

Beyond wood and stone, there is a growing demand for fabric and organic weave replications that add softness to an interior.

Performance Analysis: Technical Benefits & Limitations

To ensure a transparent specification process (and align with industry standards), it is critical to present a balanced view of the technical benefits versus the inherent limitations.

Technical Benefits

- Scuff and Scratch Camouflage: According to general performance properties outlined in NEMA LD 3, high-pressure laminates like the Unicorn MCS Laminate offer significant wear resistance. The uneven surface profile of a textured laminate visually disrupts light reflection, effectively camouflaging minor abrasions better than flat surfaces.

- Haptic Finish: Materiality affects user perception. The tactile quality adds a layer of architectural sophistication that flat colors cannot match.

Material Limitations (Trust & Transparency)

- Cleaning Regimens: While textures hide fingerprints, deep textures (such as raw wood or rough stone finishes) can trap dust, grease, and grime in the micro-crevices more than smooth surfaces. This requires specific cleaning protocols using soft nylon brushes rather than simple wiping to ensure long-term hygiene.

- Joint Visibility: Due to the core thickness (approx. 0.7mm to 1mm) and the phenolic core color (typically brown or black) of HPL, edge joints in textured applications may be visible. This requires precise finishing with matching edge bands or mitered joints to achieve a seamless look.

Application Guidelines

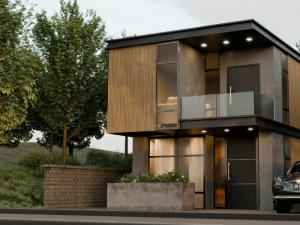

Because of their durability and aesthetic flexibility, textured laminates can be specified for various applications:

- Kitchen Cabinets: Specify Boiling Water Proof (BWP) grade plywood substrates fused with high-quality textured laminates like the Ventura Skin collection for a kitchen that is both hygienic, anti-fingerprint, and visually resilient.

- Wardrobes: A floor-to-ceiling synchronized woodgrain wardrobe using Ventura Amber Wood Laminate can act as a primary architectural feature in your bedroom. Alternatively, for a lighter, bohemian aesthetic, the Ventura Canes collection laminate is an excellent choice.

- Statement Furniture: Refurbish an existing coffee table or TV unit with a stone-finish textured laminate like the Marble & Stone laminate or the fabric-inspired Ventura Unicorn Textile MCS collection for a contemporary refresh.

Also Read : Luxury Bedroom Ideas: 12 Interior Designs for the Ultimate Retreat

Conclusion

As the Indian design landscape matures, the demand for interiors that engage the senses will only grow. Textured laminates represent the perfect intersection of biophilic aesthetics and industrial durability, allowing architects and homeowners to achieve high-end looks without the maintenance overhead of natural materials.

By understanding the technical nuances from the benefits of EIR technology found in Ventura Amber Wood to the necessity of proper maintenance you can specify these surfaces with confidence. Whether you are designing a high-traffic commercial office using Unicorn MCS Laminate or a warm residential kitchen, choosing the right texture ensures your space remains both visually striking and functionally resilient for years to come.

Frequently Asked Questions (FAQs)

1. Which one is the best laminate for interiors?

High-pressure laminates (HPL) are ideal for interiors because they are durable, scratch-resistant, easy to maintain, and available in multiple finishes and designs.

2. What are the most common interior design styles?

Modern, contemporary, minimalist, traditional, industrial, and Scandinavian are the most widely used interior design styles today.

3. What kind of laminates should we install on the kitchen cabinets?

Kitchen cabinets should use moisture- and heat-resistant HPL laminates. Matte or anti-fingerprint finishes are preferred for easy cleaning.

4. What are the different materials used for interior design?

Common interior design materials include laminates, wood, glass, metal, stone, PVC/WPC panels, and fabrics.

5. Are textured laminates suitable for high-traffic kitchens?

Textured laminates are an excellent choice for kitchens because their embossed surface creates a barrier against daily wear. Unlike high-gloss finishes, they diffuse light, meaning fingerprints and grease smudges are less visible especially when using specialized products like the Ventura Skin collection.

6. Is a textured laminate more expensive than standard laminate?

Generally, a premium textured laminate carries a moderate cost increase over basic flat laminates due to the complexity of the EIR manufacturing plates. However, it is significantly more affordable than real wood veneer or solid stone, offering a lower total cost of ownership due to reduced maintenance requirements.

7. How do you clean deep-texture laminates?

While textures hide dirt, deep grooves can trap dust if neglected. It is recommended to use a soft nylon brush or a microfiber cloth with a mild liquid cleaner to dislodge dust from the texture. Avoid abrasive steel wool or chlorinated cleaners, as these can micro-scratch the melamine overlay.

Manish Maheshwari

Position: Founder – Ventura International Pvt Ltd.

Education: IIT Roorkee (B.E. – Mechanical Engineering) and IIM Lucknow (Marketing & Finance)

Manish Maheshwari, the visionary Co-founder of Ventura International. With a background in Engineering from IIT Roorkee and an MBA from IIM Lucknow, his expertise spans across Finance, Economics, and Strategy. At the helm of Ventura’s vision, Manish leads the charge in planning and executing strategies for growth and innovation. His unwavering passion ensures that Ventura sets the bar high, always striving for unparalleled excellence.